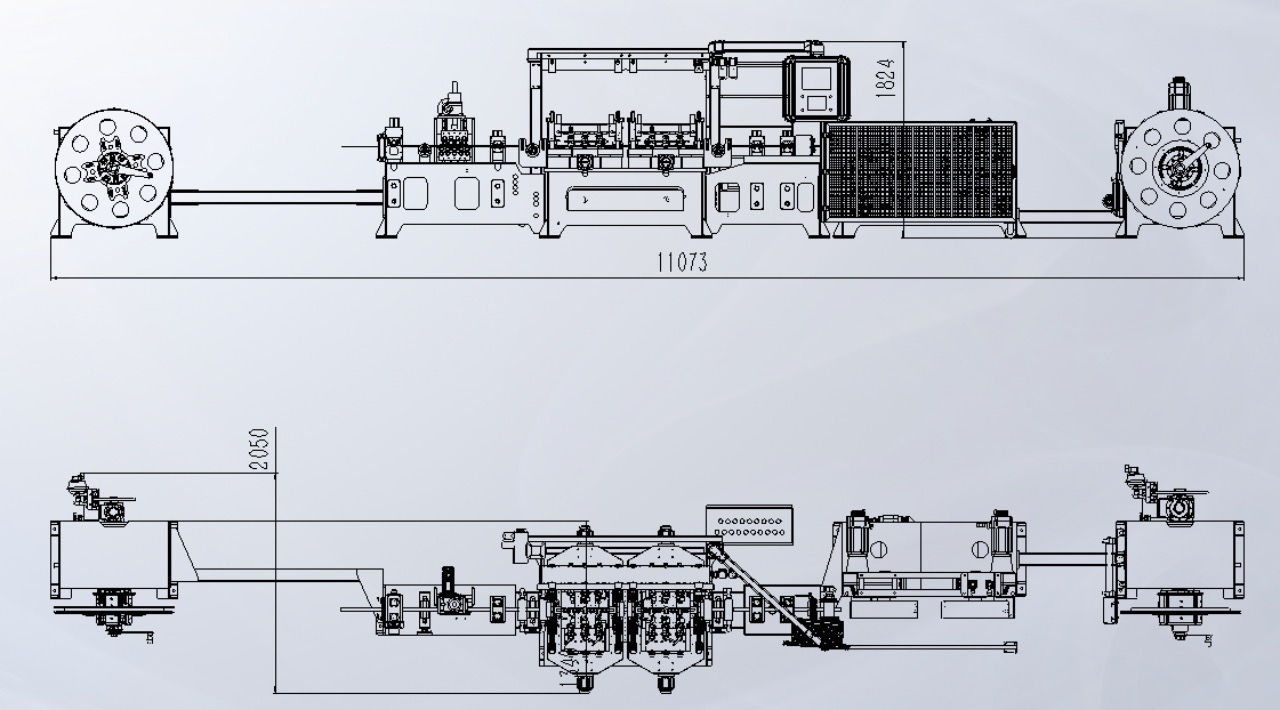

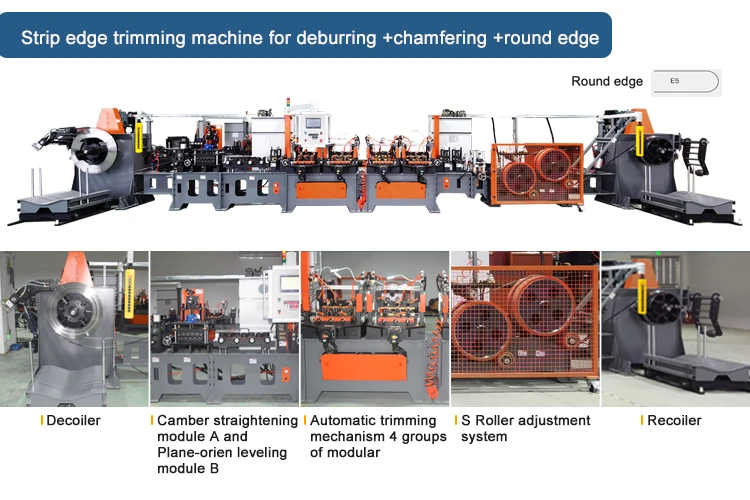

1.Trimming type for edge:deburring /chamfering /round edge 2.The material of strip:all kind of metal 3.strip width:9mm-max 30 mm 4.thickness:0.15-1.6 mm 5.Speed of machine:0-130m/min 6.Total power:24 KW 7.Cooling:air and water 8.Knives for trimming:6 pcs ,max 12 pcs 9.Occupied area:W11.0*D1.5*H1.6 M

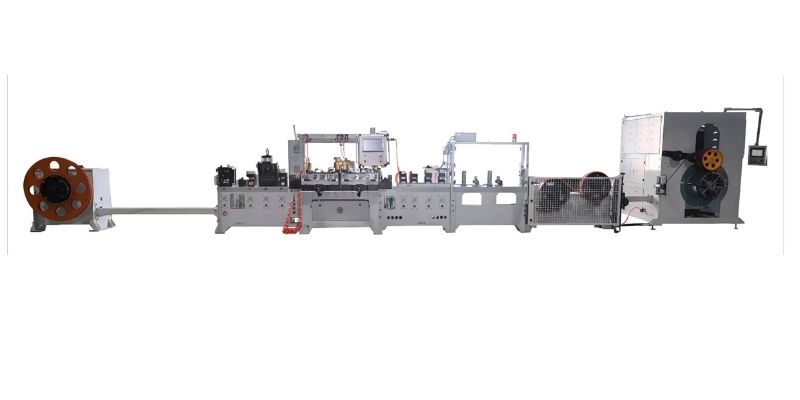

Basic specification for Strip edge trimming line with oscillating winder

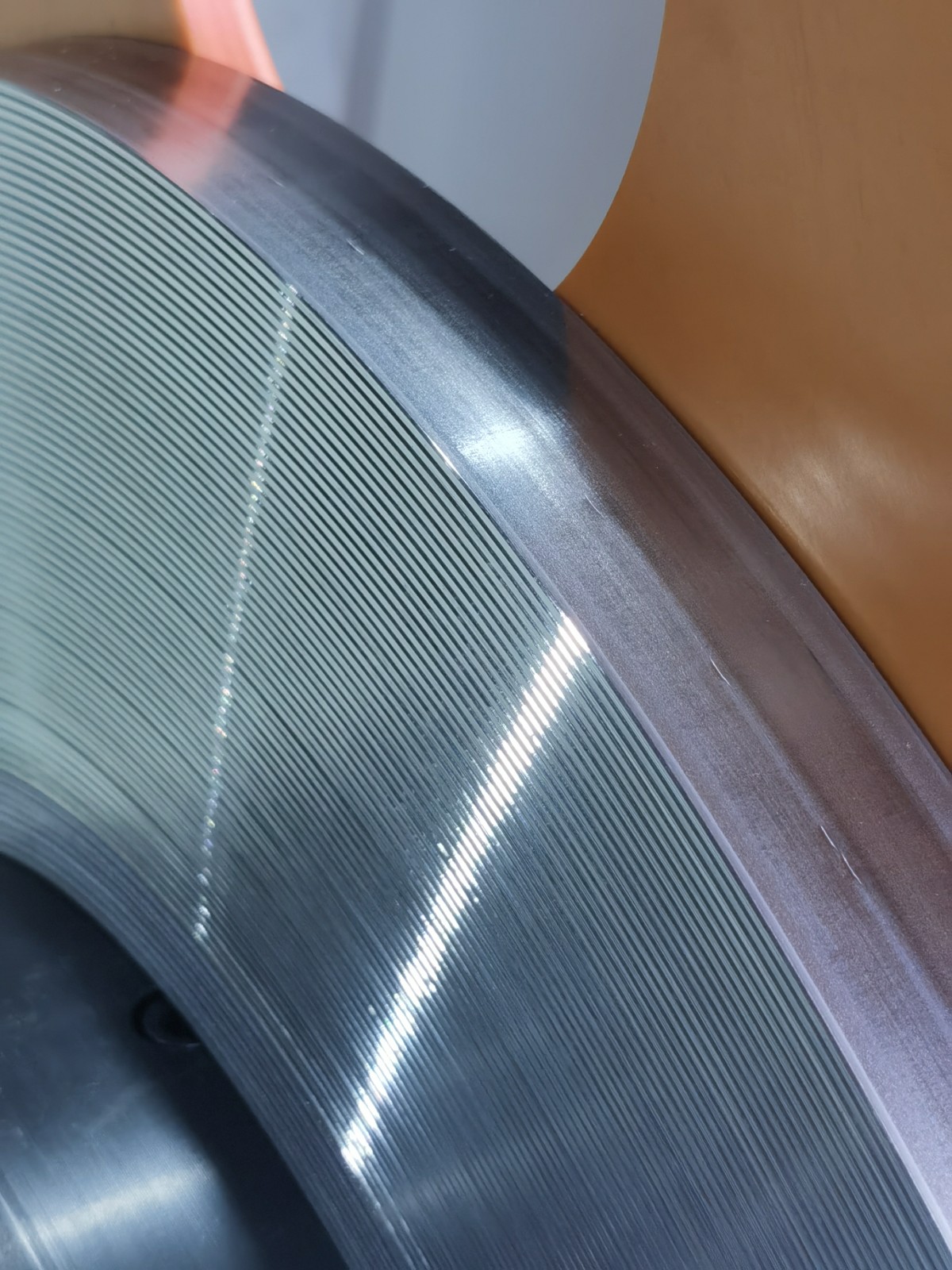

Strimming line | Strip material: carbon steel,Hi Carbon steel , stainless steel and so on Daccording to DIN EN 10088-2, According to ASTM B424 Tensile strength: 500-1000-1600N/mm² Strip width: 9 - 30mm Strip Thickness: 0.15 - 1.5mm Running speed: 0 - 150m/min adjustable (no load), the strip trimming speed depends on the material properties and trimming edge effect requirements. Electrical specifications: 380V, 50Hz, DS Control voltage: 220V, 50Hz, Solenoid valve: 24V-GS Operating direction: no later than 45 days , the Buyer must provide the information of the direction of the line Operating height: 1100mm Machine Color: 7035 Outdoor Wrinkle Industrial White Cooling method: Gas or liquid cooling (360° adjustable nozzle). ID and OD for decoiler and recoiler : size: inner diameter 500MM, maximum outer diameter 1220MM. Trimming knives: Each set can be equipped with 3 or 6 trimming knives, and up to 12 trimming knives can be installed. Scrap collection: Equipped with a drawer-type waste collection box, the height and length are increased to increase the storage capacity, and lockable universal wheels are installed at the bottom, so it can be towed directly from the rear. Trimming Knives: Trimming tool adopts general carbide blade and round-edge customized carbide blade, and the trimming method is gradual feed. Trimming shape: Deburring, chamfering, flat end face or rounding, special-shaped edge of steel strip edge. Noice of normal trimming condition : Less than 80D.but when there is a fault Occasionally ,the noice maybe is a litter bigger than 80D, ,it is not Continuous. consumption of Power :The total power of the servo motor of the equipment is about 50KW, and the power of the servo motor running during trimming is about 43KW Comsuption of air (only use air as cooling) : the minimum power of the air compressor is 22KW, if just use air as cooling. Comsuption of air and water (when use water as as cooling) :the power of the compressor is 7.5KW,and The volume of the coolant is about 145L. The water level will gradually drop according to the processing volume and usage time. When it reaches the warning position, an alarm will be sounded, and then appropriate coolant needs to be added. Control system Version for Touch screen: Chinese and English bilingual control system. Other matters: Party B may make changes to the brand and structure of the above equipment accessories according to design and technical requirements and market product supply.

|

800 type transversal rewinding machine | 800 dynamic plate precision Traversing recoiler Technology 1. Technical performance: 1.The whole is welded with high-quality steel plates to ensure quality and long-term use without deformation. The winding speed is controlled by the tension wheel, and the tension is kept constant during the winding process; the coiling is driven by the linear guide and the ball screw to drive the winding system to move forward and backward to arrange the strips, ensuring that the wire is in a straight line during the overall rewinding process without damaging the strips. 21. Used for rewinding 800 strip coils; 2. Wire specifications: width: 9-30mm; thickness 1.5-2.0mm or less; 3. There is no overlap during the material collection process; 4. The traction machine line speed is 0-150m tracking and adjustable, and the strips take-up machine automatically tracks the traction machine speed to keep the tension constant. The electric control cabinet has a reserved interface, and other processes can be configured during the rewinding process. 5. The servo controller, programmable controller, and module are of Delta brand; 6. The 800 winder can be operated with the traction machine or separately. Working environment requirements: 1. Ambient temperature is not higher than 40℃; 2. Voltage and fluctuation: 380V±10%; 3. Frequency: 50Hz±2%; 2. Technical parameters and instructions: 800 traversing rewinding machine NoNameSpecifications, parameters and indicators1Traversing recoilerExpanding and shrinking mandrel, outer paper tube winding2Applicable specifications:(mm)Maximum winding diameter: φ1220Strip Inner diameter of strip wheel: φ500Drum width: Maximum width 400 mm3Mandrel center height800 mm4Single bearing weight1000kg5Traversing rewinding powder15kw variable frequency motor with reducer (optional servo motor torque mode winding, torque adjustable)6Pay-off tension10kg magnetic powder damping pay-off7Traversing methodServo motor ball screw cable (PMI)8Traversing railYintai 45 Linear Guide (PMI)9Tension range200N(Tension accuracy ±20%)10Operation method10 Inch touch screen and button operation11Speed0-150m/min12Meter Accuracy<3‰ 13 Effective distance of cable traverse 500mmThe 800 traversing -rewinder machine includes: a fixed base frame, a mobile frame, a wire arrangement mechanism, a transmission part, a wire drum expansion and contraction part, a strips pressing part, and an electric control cabinet. Base frame and mobile frame: Made of high-quality steel, welded by CO2 gas shielded welding, and processed after aging treatment. The mobile frame is installed on the linear guide rail on the low frame, and reciprocates through the ball screw connection transmission to complete the wire arrangement action, ensuring the stable and reliable performance of the whole machine after assembly. Wire arrangement mechanism adopts PMI linear guide rails and ball screws to ensure the accuracy of strips arrangement. A servo motor is installed at one end to drive the mobile frame of the strip-receiving and strip-releasing machine to reciprocate wire arrangement through the ball screw. Transmission part The power is transmitted from the output of the 15kw servo motor to the reducer, and the reducer is transmitted to the spindle. Finally, the coupling disk at the front end of the spindle drives the strips-receiving and wire-reducing reel to rotate. Wire drum expansion and contraction part The whole is divided into 4 plates. In order to improve the expansion and contraction roundness, a slider mechanism is used for expansion and contraction. The expansion and contraction spindle sleeve adopts a detachable structure and is connected to the transmission spindle keyway bolt. The inner sleeve at the front end of the transmission main shaft expands and contracts, and the expansion and contraction of the expansion and contraction part is controlled by turning the handle. Strip pressing part When the wire arrangement is used, the wire pressing part is at a high position. When the strip arrangement function is not used for winding, the strip passing speed regulating lifting frame is at a high position, the strip pressing wheel is pressed down to the specified position, and after winding to a certain number of layers, the wire pressing wheel rises a certain distance, and the touch screen displays the current strip pressing wheel position in real time. The distance between the strip pressing wheel shaft and the winding reel makes the wire taking-up positioning wheel and the winding reel at a suitable distance to ensure that the strips does not collapse, and the up and down adjustment is controlled by a stepper motor lead screw. Wire passing wheel at the feeding end. The strips feeding guide wheel part is installed on the sliding table lifting as a whole, so that the strips feeding fixed wheel is as close to the strips reel as possible to ensure the quality of wire arrangement. 。 C. Control method: a. The strip arrangement collects the encoder signal of the servo strips taking-up motor through the PLC to calculate, so that the strips arrangement mechanism keeps synchronization with the wire taking-up. b. The speed of the strip is collected by driving the photoelectric encoder through the strip wheel to feedback to the PLC to achieve the accuracy of the meter and wire speed. D. Strip traversing arrangement technology: After years of careful research, development, practice and summary by our company, an effective wire arrangement method has been developed to effectively solve the problem of strip advance or lag caused by strip stacking and reversing during the wire arrangement process, and the current position of the strip arrangement is displayed in real time to ensure the flatness of the wire arrangement. |

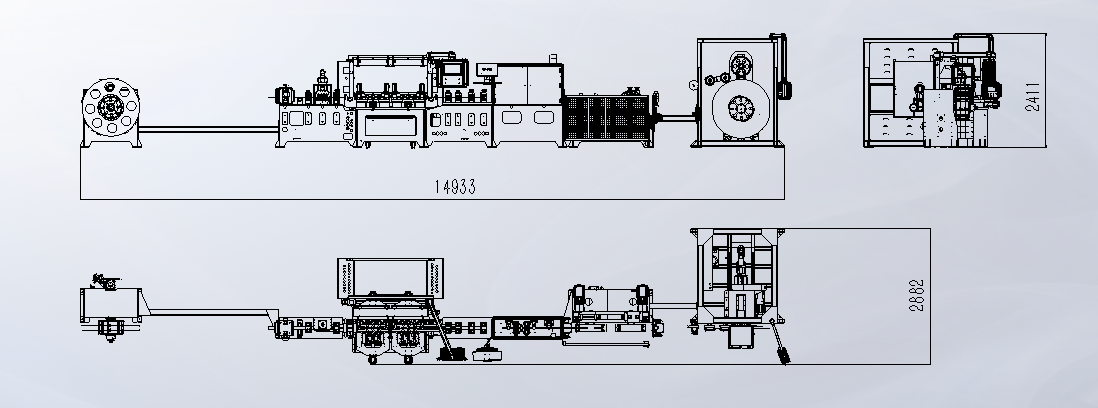

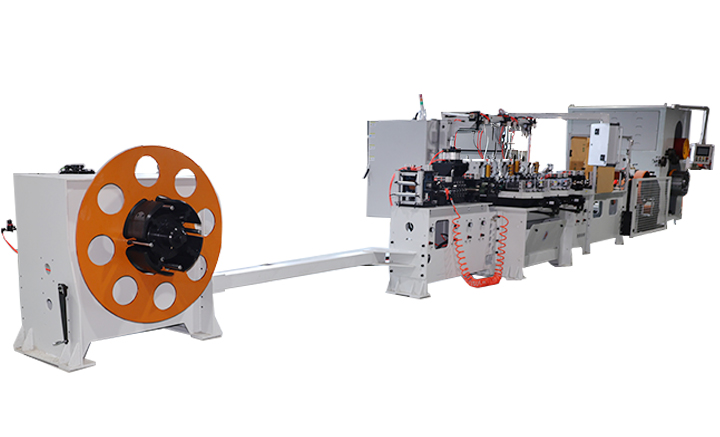

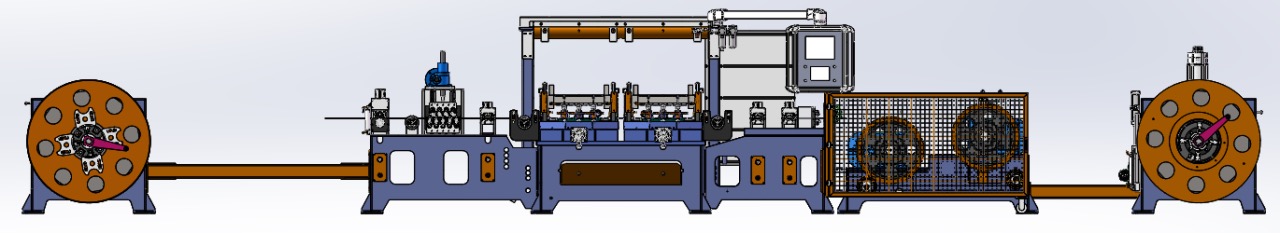

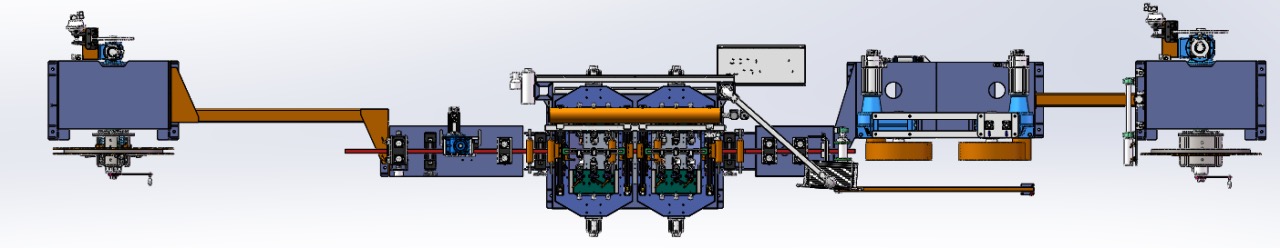

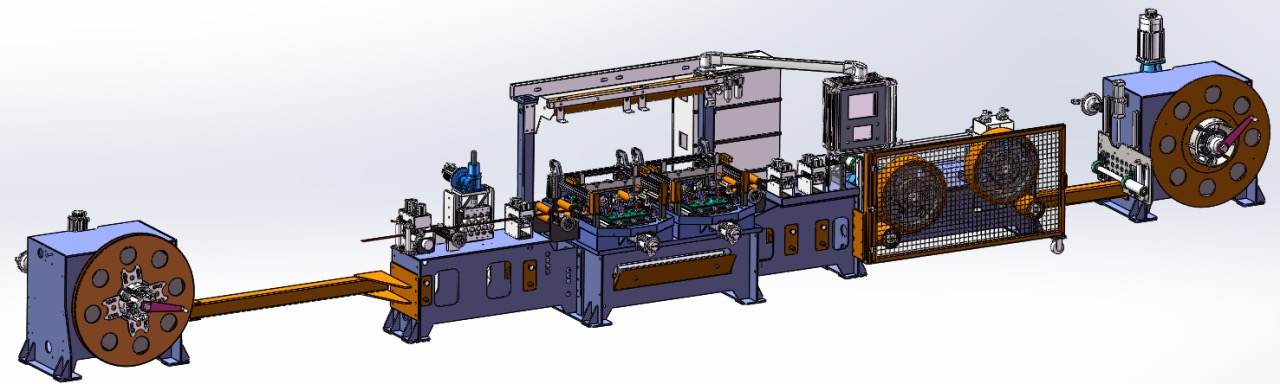

3D renderings of the equipment for reference :(The layout in the following figure is for reference only, and is not intended to describe the final device shape in this solution)

<span data-mce-style="margin: 0px; padding: 0px; border: 0px; font-style: inherit; font-weight: inherit; font-size: inherit; line-height: 27px; font-family: Calibri; vertical-align: baseline;" style="line-height: 27px; margin: 0px; padding: 0px; border: 0px; font-

Contact: Mike Chen

Phone: +86-15815989367

Tel: +86-15815989367

Email: info@gmachinery.cn

Add: Add 1:Pengkang 5G Technology Park, Lunjiao Street, Shunde District, Foshan City, Guangdong Province /Add 2:6-No.1 West end of pingshengshenglong industrial park ,Pingzhou of guicheng street,nanhai district, Foshan city ,Guangdong province of China